How to Design and Implement a High-Efficiency Packaging Line: A Step-by-Step Whitepaper

In today's fast-paced manufacturing and logistics environment, a well-designed packaging line is no longer a luxury—it's a critical component of operational efficiency, cost control, and brand protection. This whitepaper, presented by Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd. (Shuangcheng Packaging), serves as a comprehensive, step-by-step guide for engineers, operations managers, and business owners looking to design, optimize, or implement a high-performance automated packaging system. We will integrate insights from our nearly two decades of experience, our core products like Shrink Wrap Machines, Carton Sealers, and automatic strapping machines, and the latest industry trends driving automation.

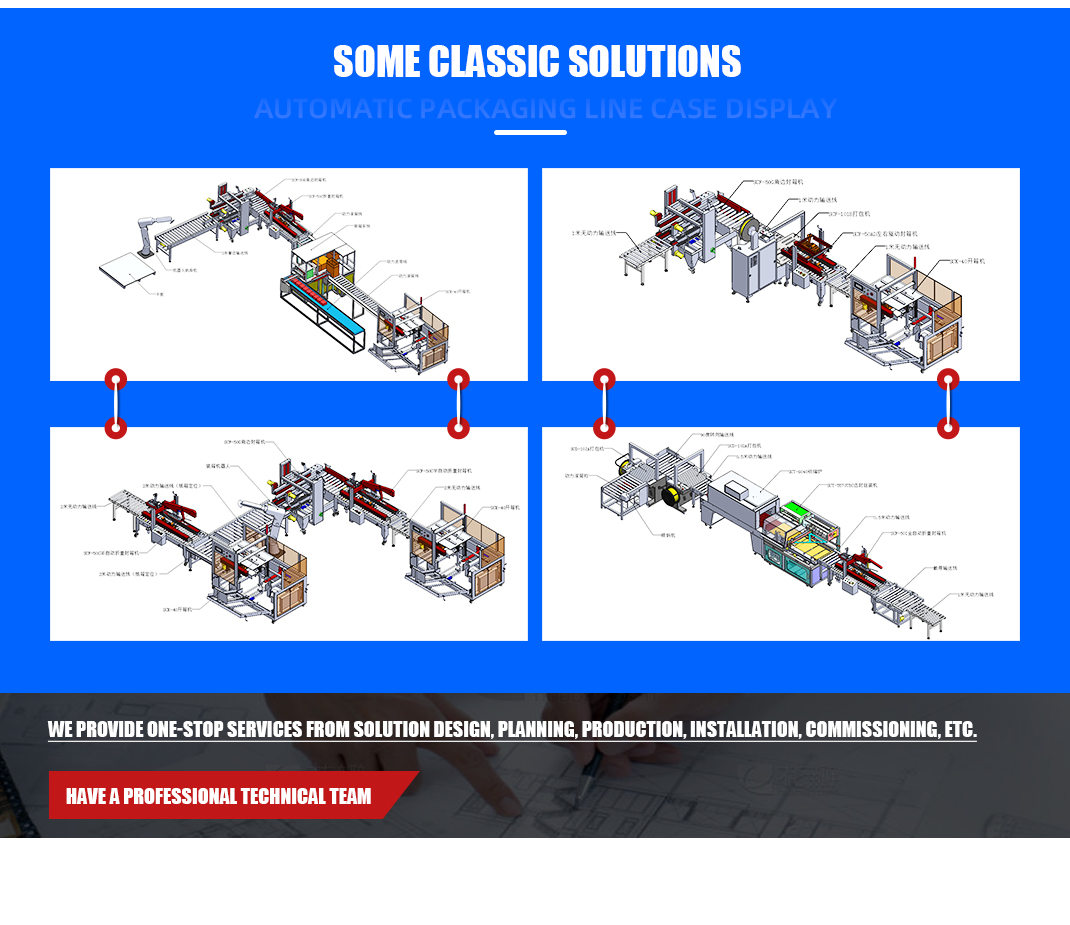

Figure 1: A custom-integrated packaging line solution designed by Shuangcheng Packaging, showcasing seamless machine-to-machine workflow.

Phase 1: Needs Assessment & Strategic Planning

The foundation of any successful packaging line project is a thorough understanding of your current and future needs.

Step 1: Define Your Product and Volume Profile

- Product Characteristics: Size, weight, shape, fragility, and material (e.g., electronics requiring E-commerce-packaging-machine solutions or food items needing a Fully automatic vacuum packaging machine).

- Production Volume & Peaks: Average daily output, seasonal spikes (critical for Express packaging machine operations), and projected growth over 3-5 years.

- Packaging Specifications: Required package types (carton, shrink wrap, bag), sealing methods, and labeling requirements.

For instance, an e-commerce fulfillment center might require a line starting with a high-speed Carton Erector (like Shuangcheng's SCK-40DS), followed by an automatic bagging machine for inner protection, and ending with an I-shaped Carton Sealer.

Step 2: Analyze Your Current Process & Bottlenecks

Map your existing manual or semi-automatic process. Identify slowdowns: Is it the manual taping of boxes, the slow application of shrink film, or inefficient palletizing? Quantify the labor hours, error rates, and material waste. This analysis directly informs which Packaging Machine types will deliver the highest ROI.

Phase 2: Line Design & Machine Selection

This phase translates your needs into a technical blueprint.

Figure 2: Shuangcheng's fully automatic servo Carton Erector, forming up to 40 boxes per minute.

Step 3: Selecting Core Packaging Machines

Choose equipment based on the defined workflow. A typical end-to-end line may include:

- Forming: Carton Erectors or Bagging machines for primary packaging.

- Loading/Filling: Often manual or robotic, integrated with the former.

- Sealing/Closing: Carton Sealers (tape or glue) or Shrink Wrap Machines (like Shuangcheng's SCT-5545TBD for L-sealing).

- Securing: Automatic strapping machines (e.g., Shuangcheng's SCD-301 for bundle stability).

- Unitizing: Palletizer (robotic or column type) for final load formation.

Key Consideration: Ensure machine compatibility in terms of speed, product handling interfaces, and communication protocols (e.g., PLC controls).

Step 4: Integration & Control Systems

The true power of a packaging line lies in its integration. This involves:

- Conveyor Systems: Selecting the right type (belt, roller, chain) to link machines smoothly.

- Control Software: A central PLC or industrial PC, like Shuangcheng's proprietary control systems shown in our certifications, to synchronize all machines, manage speeds, and collect OEE data.

- Safety & Ergonomics: Incorporating guards, light curtains, and ergonomic workstations.

Shuangcheng Packaging, as a national high-tech enterprise, leverages its patented control system technology to create cohesive, smart lines where a Shrink Wrap Machine communicates seamlessly with a downstream automatic strapping machine.

Industry Trend Spotlight: The Rise of Flexible & Sustainable Lines

Recent dynamics, including labor shortages and e-commerce growth, are pushing for lines that handle diverse SKUs (requiring quick-change Bagging machine heads or adjustable Carton Sealers) and sustainable materials. Modern Shrink Wrap Machines are now optimized for thinner, recyclable films, while Fully automatic vacuum packaging machines reduce food waste—a key selling point. Shuangcheng's R&D team continuously adapts products like our E-commerce-packaging-machine series to these trends.

Phase 3: Implementation & Optimization

Step 5: Installation, Commissioning, and Staff Training

Professional installation is crucial. A reputable supplier like Shuangcheng Packaging provides on-site engineers for assembly, calibration, and testing of the entire packaging line. Comprehensive training for your operators and maintenance staff on each Packaging Machine is essential for long-term success and safety.

Figure 3: Precision assembly of an automatic strapping machine at Shuangcheng's 5000 sqm production workshop in Shenzhen.

Step 6: Continuous Monitoring and Lean Optimization

After go-live, monitor key metrics: line speed, downtime, pack quality, and material usage. Use this data to fine-tune machine settings. For example, optimizing the heat tunnel temperature on a Shrink Wrap Machine can reduce energy use and film waste. The goal is a lean, agile operation.

Why Partner with Shuangcheng Packaging for Your Line Project?

Founded in 2005 and adhering to the principle of "honesty is the foundation of business, integrity is the source of development," Shuangcheng Packaging offers more than just individual machines. We provide turnkey packaging line solutions.

- End-to-End Expertise: From Carton Erectors and Fully automatic vacuum packaging machines to Palletizers, we manufacture the core components, ensuring compatibility.

- Proven Technology: Our multiple core control system patents, visible in our certification documents, enable intelligent, reliable automation.

- Global Recognition: Our Packaging Machine solutions are not only popular domestically but are also exported to India, Vietnam, Southeast Asia, and Europe, trusted by clients like SF Express and BYD.

- Comprehensive Support: We offer professional technical consultation, system integration support, and after-sales service to keep your line running at peak performance.

Ready to Transform Your Packaging Operations?

Designing an efficient packaging line is a strategic investment. By following this whitepaper's steps and partnering with an experienced provider, you can achieve significant gains in productivity, consistency, and cost-efficiency.

Contact Shuangcheng Packaging today for a free, no-obligation consultation on your packaging automation needs.

📞 Phone: +86-13823631165

📧 Email: scpack@163.com

🌐 Website: www.shuangchengpack.com

🏢 Address: Building A6, No. 8 Xiongyu Road, Tangxiayong Community, Yanluo Street, Baoan District, Shenzhen, Guangdong, China