Navigating the Maze of Shrink Wrap Machinery: Your Path to Packaging Efficiency

In today's fast-paced manufacturing and logistics sectors, the right packaging solution isn't just a luxury—it's a critical component of operational efficiency and product presentation. With the global push towards automation and smart manufacturing, selecting the appropriate Shrink Wrap Machine has become more complex, yet more vital than ever. Recent industry reports highlight a significant trend: businesses are moving away from generic, one-size-fits-all packaging towards customized, high-speed automated solutions that integrate seamlessly into existing production lines. This shift is driven by the need for higher throughput, reduced labor costs, and consistent, high-quality packaging that protects products and enhances brand image on the shelf.

As a leading force in intelligent packaging since 2005, Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd. understands these challenges intimately. With our 5000 square meter R&D and production facility in Shenzhen, we've dedicated nearly two decades to engineering solutions that bridge the gap between manual processes and full automation. This guide will walk you through the key considerations, helping you make an informed decision that aligns with your specific production needs, budget, and future growth plans.

A Fully automatic high speed side seal shrink wrap machine like the SCT-5545TBH can dramatically increase packaging line output.

Step 1: Assess Your Product and Production Volume

The first and most crucial step is a thorough analysis of what you're packaging and how much of it you need to package.

- Product Dimensions & Shape: Are your products uniform (like books or software boxes) or irregular (like tool kits or assembled goods)? For standard rectangular items, a Servo side seal shrink machine offers excellent efficiency. For taller or more complex items, an L-type machine might be necessary. Shuangcheng's Non-standard side seal shrink wrap equipment is specifically designed for unique product profiles that fall outside typical dimensions.

- Production Speed (Units Per Hour): This is the heart of the decision. Low to medium volume operations (a few hundred packages per hour) might benefit from a semi-automatic system. For high-volume environments like e-commerce fulfillment centers or large-scale manufacturing, a Fully automatic high speed side seal shrink wrap machine is non-negotiable. Our SCT-5545TBH model, for instance, is engineered for blistering speeds without compromising seal integrity.

- Packaging Material: The type of shrink film (PVC, POF, PE) you plan to use can influence the machine's sealing and shrinking tunnel specifications. Discuss your material choice with your supplier.

Step 2: Understand the Core Machine Types and Their Applications

Not all shrink wrappers are created equal. Here’s a breakdown of key technologies from Shuangcheng's portfolio:

The Fully automatic L-type shrink wrap machine (SCT-5545TBA) is ideal for bundling multiple products or packaging tall items.

- L-Type Sealers: Machines like our Servo vertical up and down L-type heat shrink packaging machine (SCT-6560TBD) create a seal on the back and bottom of the film, forming an "L" shape. They are perfect for bundling multiple products together (multi-packs) or for items that are too tall for a standard side seal. The "servo vertical up and down" mechanism allows for precise, adjustable sealing for different product heights.

- Side Seal (Sleeve) Wrappers: This is one of the most common types. The film is wrapped around the product and a vertical seal is made on the side. Our Servo side seal Shrink Wrap Machine (SCT-5545TBC) uses servo motors for exceptional control over film feeding and sealing, reducing film waste and ensuring perfect seals every time. For even higher throughput, the Fully automatic high speed variant is the go-to choice.

- Horizontal Seal Rear Wrappers: For products that require a more enclosed package or a specific presentation, a Horizontal seal rear shrink film wrapping machine (SCT-5570TBZ) seals the film at the rear, creating a neat, tamper-evident package that's great for retail.

- Integrated Systems: For operations requiring bagging before shrinking, consider a combined solution. A Fully automatic bagging machine can feed into a shrink tunnel. For products requiring oxygen barrier protection, a Fully automatic bagging vacuum packaging machine might be the first step in your line.

Step 3: Evaluate Automation Level and Integration Potential

Automation is the key to scaling your business. The level you choose depends on your labor availability and long-term strategy.

- Manual/Semi-Automatic: Requires an operator to place the product. Suitable for low volume, high-mix scenarios.

- Fully Automatic: These systems, like our Fully automatic L-type shrink wrap machine, integrate with conveyors and upstream/downstream equipment (like carton erectors or case sealers). They automatically feed, wrap, seal, and shrink the product with minimal human intervention. This is where Shuangcheng's expertise in "back-end packaging assembly lines" truly shines.

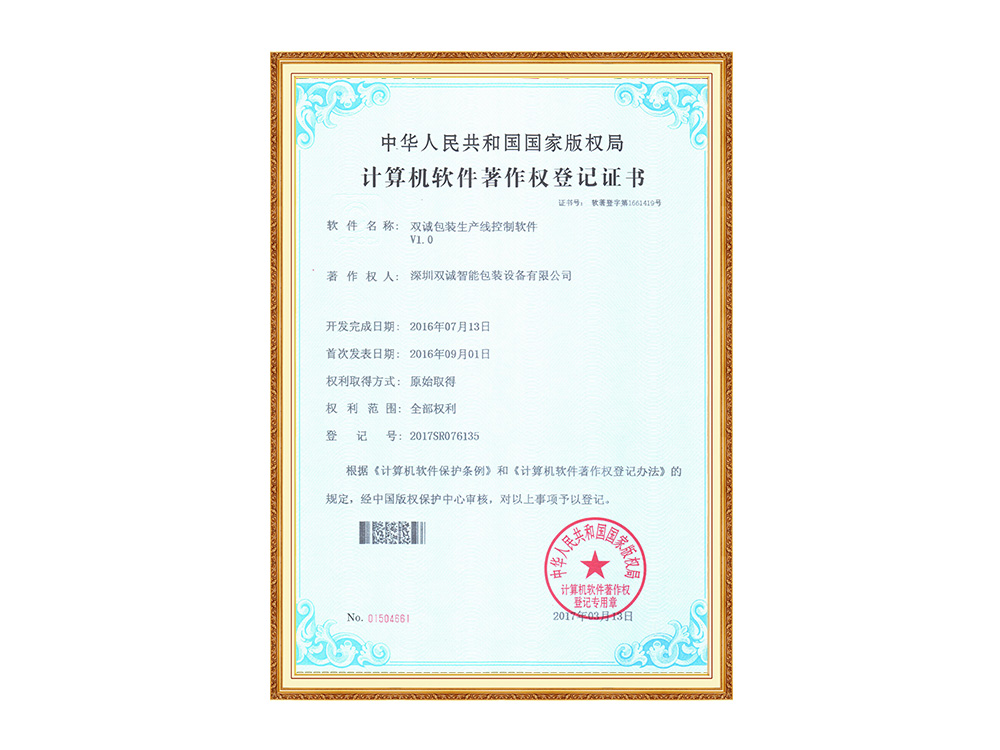

- Servo-Driven Intelligence: The pinnacle of precision. Servo L-type sealing, cutting and Shrink Wrap Machine models use computer-controlled servo motors for every movement—film feeding, sealing, cutting. This guarantees repeatable accuracy, allows for quick changeovers via a touchscreen interface, and significantly reduces film waste. Our proprietary control software, evident in our patented systems, makes this complexity simple to operate.

Shuangcheng's intelligent control software allows for easy management of complex Shrink Wrap Machine parameters and production line integration.

Step 4: Consider the Manufacturer's Credentials and Support

The machine is only as good as the company behind it. Here’s what to look for:

- Experience & Reputation: Shuangcheng Packaging, as a national high-tech enterprise, has been refining its technology since 2005. Our client list, including giants like SF Express and BYD, speaks to our reliability and performance.

- Technical Innovation: Look for patents and proprietary technology. We hold multiple core control system technology patents, ensuring our machines are not just assembled, but intelligently engineered.

- Global Service & Parts Network: With exports to India, Vietnam, Southeast Asia, and Europe, we understand the need for robust after-sales support. Ensure your supplier can provide timely technical consultation, spare parts, and maintenance guidance.

- Customization Ability: Can they build a Non-standard side seal shrink wrap equipment solution if your product demands it? Shuangcheng's strong R&D team is equipped to handle special requests.

State-of-the-art manufacturing equipment at the Shuangcheng facility ensures precision parts for every Shrink Wrap Machine.

Step 5: Plan for the Future

Your packaging needs will evolve. Choose a partner and a machine that can grow with you. A modular Servo side seal shrink machine from Shuangcheng can often be upgraded or reconfigured. Consider your plans for new product lines, increased capacity, or integration with other Carton Sealers and Palletizers for a complete end-of-line solution.

Making the Final Decision with Shuangcheng Packaging

Choosing the right Shrink Wrap Machine is a strategic investment. By methodically working through these steps—analyzing your product, understanding machine types, defining automation needs, vetting the manufacturer, and future-proofing—you can select a system that delivers immediate ROI and long-term value.

At Shuangcheng Intelligent Packaging, we live by our motto: "Honesty is the foundation of business, integrity is the source of development." We're more than just a vendor; we're a partner in your packaging success. Whether you need a robust Fully automatic bagging vacuum packaging machine for food products or a high-speed Servo L-type sealing, cutting and Shrink Wrap Machine for consumer goods, our team is ready to provide a tailored solution.

Ready to optimize your packaging line? Contact Shuangcheng Packaging today for a professional consultation. Let us help you wrap up your efficiency challenges, for good.

Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd.

Website: www.shuangchengpack.com

Email: scpack@163.com

Tel: +86-13823631165

Address: Building A6, No. 8 Xiongyu Road, Tangxiayong Community, Yanluo Street, Baoan District, Shenzhen, Guangdong, China