Market Data Overview

According to recent industry analysis, the global Packaging Machine market is projected to grow from USD 48.2 billion in 2024 to over USD 68.5 billion by 2030, registering a steady CAGR of approximately 6.1%. This growth is fueled by the relentless expansion of e-commerce, the demand for supply chain efficiency, and the global push towards automation and sustainable packaging solutions. For industrial buyers, navigating this vast and competitive supplier landscape requires a clear understanding of the logic behind market rankings.

Ranking Dimensions: How Are Packaging Machine Suppliers Evaluated?

When assessing the top players in the Packaging Machine sector, several core dimensions form the basis of any credible market ranking. Understanding these helps buyers look beyond simple lists.

- Market Share & Revenue: This quantifies a company's commercial success and scale. Leaders often have a diverse global clientele and significant export volumes, indicating proven reliability.

- Technological Innovation & R&D: A critical differentiator. Leaders invest in advanced features like servo-driven controls, IoT integration for predictive maintenance, and AI-powered vision systems for quality checks. Patents held, such as those for core control systems, are a key indicator.

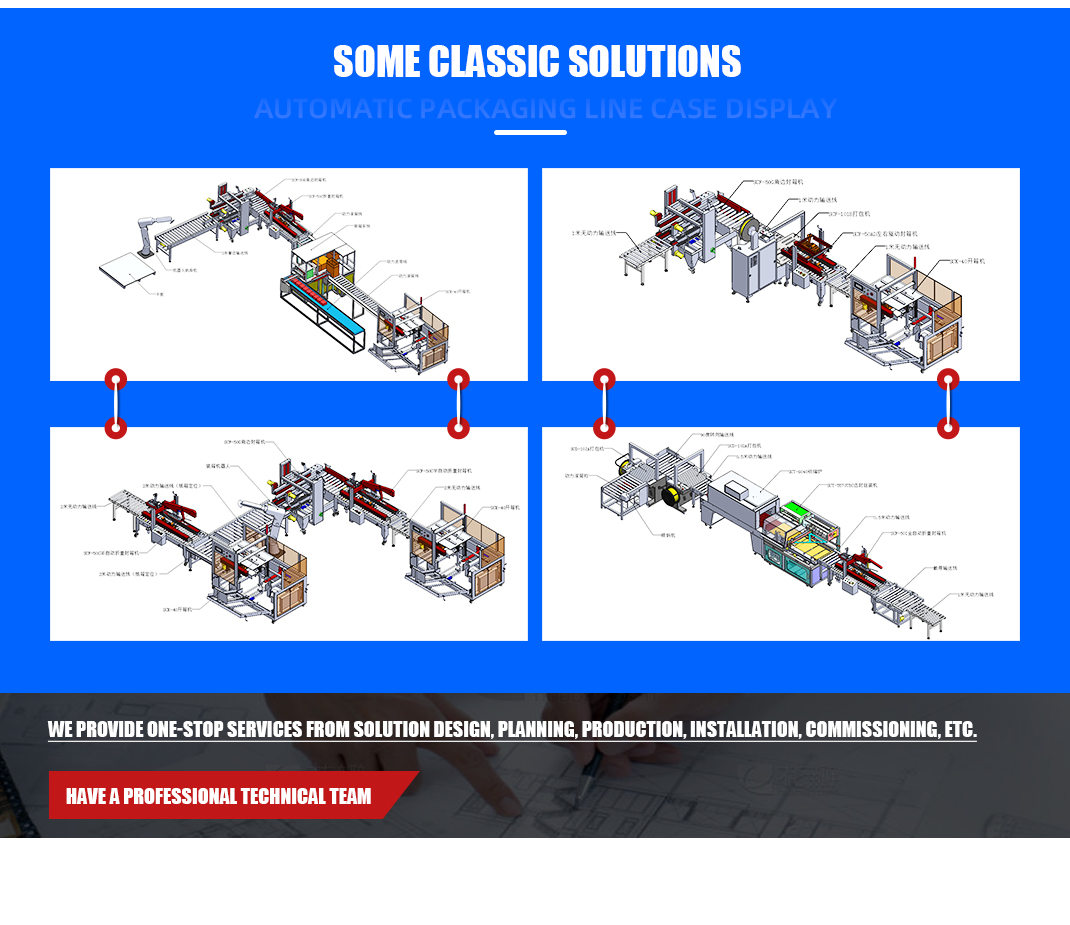

- Product Portfolio & Solution Breadth: The ability to supply not just single machines like a Shrink Wrap Machine or Carton Sealer, but also complete, customized packaging line solutions is a mark of a top-tier supplier. This includes integration of Carton Erectors, Automatic Strapping Machines, Palletizers, and Bagging Machines.

- Client Portfolio & Industry Recognition: Endorsement by major, demanding clients (e.g., global logistics firms like SF Express or automotive giants like BYD) serves as powerful third-party validation of product performance and after-sales support.

- Manufacturing Capability & Certifications: A modern production facility, stringent quality control (evidenced by ISO 9001 certification), and compliance with international safety standards (CE, UL) are non-negotiable for global suppliers.

Modern manufacturing infrastructure, like that of Shuangcheng Packaging, is a cornerstone of reliable, high-volume production.

The Global Market Structure: Three Distinct Tiers

The global supplier landscape for Packaging Machines can be broadly segmented into three tiers:

- International Premium Brands: Historically dominant European, North American, and Japanese players. They are renowned for ultra-high precision, robust engineering for 24/7 operation, and strong brand legacy. Their solutions often come at a premium price and are typically chosen for large-scale, capital-intensive projects where maximum uptime is critical.

- Chinese High-Value Manufacturers: This group has dramatically reshaped the market. Companies like Shuangcheng Packaging exemplify this tier. They combine advanced technology (servo systems, smart controls), significant customisation capability, rapid production cycles, and highly competitive pricing. As highlighted in the recent article "China's Top Three Packaging Machinery Manufacturers - Leading the World in Packaging Automation", these manufacturers are now leaders in automation, offering solutions that rival international brands in performance but with better cost-effectiveness.

- Regional & Niche Specialists: Suppliers focusing on specific regions or particular machine types (e.g., only Fully automatic vacuum packaging machine for local food processors). They compete on deep local market knowledge and service but may lack the scale and R&D breadth of the top two tiers.

High-speed automation, such as in this Carton Erector, is a key strength of leading Chinese manufacturers.

The Rise of Chinese Suppliers: Key Ranking Advantages

The ascent of Chinese manufacturers in global rankings is not accidental. It is built on concrete competitive advantages that directly address buyer pain points:

- Integrated Cost-Quality Proposition: Leveraging mature supply chains and large-scale manufacturing in facilities like the 5,000 sqm workshop of Shuangcheng Packaging, they deliver high automation levels without the premium price tag, offering an exceptional return on investment.

- Agile Customization & Rapid Response: Unlike larger multinationals with rigid product lines, companies like Shuangcheng excel at tailoring machines. Whether it's an E-commerce-packaging-machine for variable parcel sizes or a special Express packaging machine solution, their engineering teams can adapt quickly, reducing time-to-market for buyers.

- Technology Adoption & Patents: Heavy investment in R&D has closed the technology gap. For instance, Shuangcheng holds multiple core technology patents for control systems, ensuring their Automatic Strapping Machine or Palletizer operates with precision and reliability.

- Global Compliance & Export Readiness: Top Chinese suppliers design for the global market. Their machines are built to meet international standards (CE, etc.), and they have established export channels to regions like Southeast Asia, Europe, and India, proving their global service capability.

Strategic Procurement Advice: Matching Your Needs to the Right Tier

A market ranking is a starting point, not the final answer. The "best" supplier depends entirely on your specific operational and financial context.

- For Large-Scale, Greenfield Projects with High Uptime Demands: Consider Tier 1 international brands. The investment is justified for mission-critical, high-throughput lines where long-term engineering support and a proven track record in extreme conditions are paramount.

- For Most SMEs and Cost-Sensitive Automation Projects: The high-value Chinese Tier 2 manufacturers are often the optimal choice. If you need a reliable Shrink Wrap Machine, a semi-automatic Carton Sealer, or a compact packaging line, companies like Shuangcheng Packaging (www.shuangchengpack.com) offer the best balance of technology, price, and support. Their recognition by major firms validates their capability for serious industrial use.

- For Very Specific, Localized Needs: A regional Tier 3 specialist might offer the most hands-on service and niche expertise for a unique application, though scalability for future growth may be limited.

Actionable Step: Always request detailed case studies or client references relevant to your industry. For example, if you are in electronics, ask a potential supplier like Shuangcheng about their Bagging machine solutions for 3C products. Visit their facility virtually or in person to assess their packaging line integration capabilities.

The ability to design and integrate complete packaging line solutions is a key differentiator for top-ranked suppliers.

Conclusion and Outlook

The Packaging Machine market ranking is a dynamic reflection of innovation, value, and global supply chain evolution. While traditional powerhouses remain strong, the decisive shift towards Chinese high-value manufacturers is the defining trend. For the pragmatic industrial buyer, the goal is not to find the "#1 ranked" company in isolation, but to identify the supplier whose strengths—be it in cutting-edge technology for a Fully automatic vacuum packaging machine, cost-effective automation for a Carton Erector, or total solution design—most precisely align with your operational requirements, budget, and growth trajectory. By understanding the logic behind the rankings, you can make an informed, strategic partnership choice that drives efficiency and competitiveness for years to come.

For a deeper dive into leading automation solutions, explore the innovative portfolio of Shuangcheng Packaging, a nationally recognized high-tech enterprise, at their official website: www.shuangchengpack.com. Contact their team at scpack@163.com or +86-13823631165 to discuss your specific Packaging Machine needs.