A Practical Guide to Selecting the Perfect Shrink Wrap Machine

In today's fast-paced manufacturing and logistics sectors, efficiency and presentation are paramount. A shrink wrap machine is no longer a luxury but a necessity for businesses looking to protect products, enhance shelf appeal, and streamline operations. However, with a myriad of options available—from fully automatic high speed side seal shrink wrap machines to specialized non-standard side seal shrink wrap equipment—selecting the right one can be daunting. This guide, drawing on the expertise of industry leader Shuangcheng Packaging, will walk you through the key considerations to make an informed decision that boosts your productivity and bottom line.

Why Your Choice of Shrink Wrapper Matters

The global packaging automation market is witnessing significant growth, driven by e-commerce expansion and the need for sustainable, efficient solutions. A well-chosen machine not only secures your products but also reduces material waste, lowers labor costs, and ensures consistent, professional packaging—critical factors for brands like SF Express and BYD, who trust partners like Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd.

Step 1: Analyze Your Product and Production Needs

The first step is a thorough audit of what you're packaging.

- Product Size & Shape: Irregular items? Consider a versatile Servo L-type sealing, cutting and Shrink Wrap Machine like the SCT-5545TBD from Shuangcheng, which handles diverse geometries with precision.

- Production Volume: High-output lines demand a fully automatic high speed side seal shrink wrap machine. For lower volumes, a semi-automatic model might suffice initially.

- Packaging Material: Determine if you need a standard polyolefin film or specialized barrier films, which might influence the sealing and heating technology required.

Shuangcheng's SCT-5545TBH: A fully automatic high speed side seal shrink wrap machine designed for high-volume production.

Step 2: Understand the Different Machine Types

Here’s a breakdown of common shrink wrap machine types and their best-use scenarios.

| Machine Type | Key Features | Ideal For |

|---|---|---|

| L-Type Sealers (e.g., Fully automatic L-type shrink wrap machine) | Forms an "L"-shaped seal, excellent for bundling multiple items or tall products. | Bundling books, cans, bottles, and promotional packs. |

| Side Seal/Sleeve Wrappers (e.g., Servo side seal shrink machine) | Creates a sealed sleeve around the product. High speed and efficient. | Food boxes, software, cosmetics, and standard-shaped consumer goods. |

| Horizontal Seal Rear Wrappers (e.g., Horizontal seal rear shrink film wrapping machine SCT-5570TBZ) | Seal is at the rear, offering a clean, presentation-friendly finish on three sides. | Retail-ready packaging where visual appeal is critical. |

| Integrated Systems (e.g., Fully automatic bagging vacuum packaging machine) | Combines bagging, vacuumizing, and sealing in one automated process. | Food preservation, industrial components requiring barrier protection. |

Step 3: Evaluate Automation and Technology Level

Automation is key to reducing labor costs and human error. Shuangcheng Intelligent emphasizes servo-driven technology for its precision and energy efficiency.

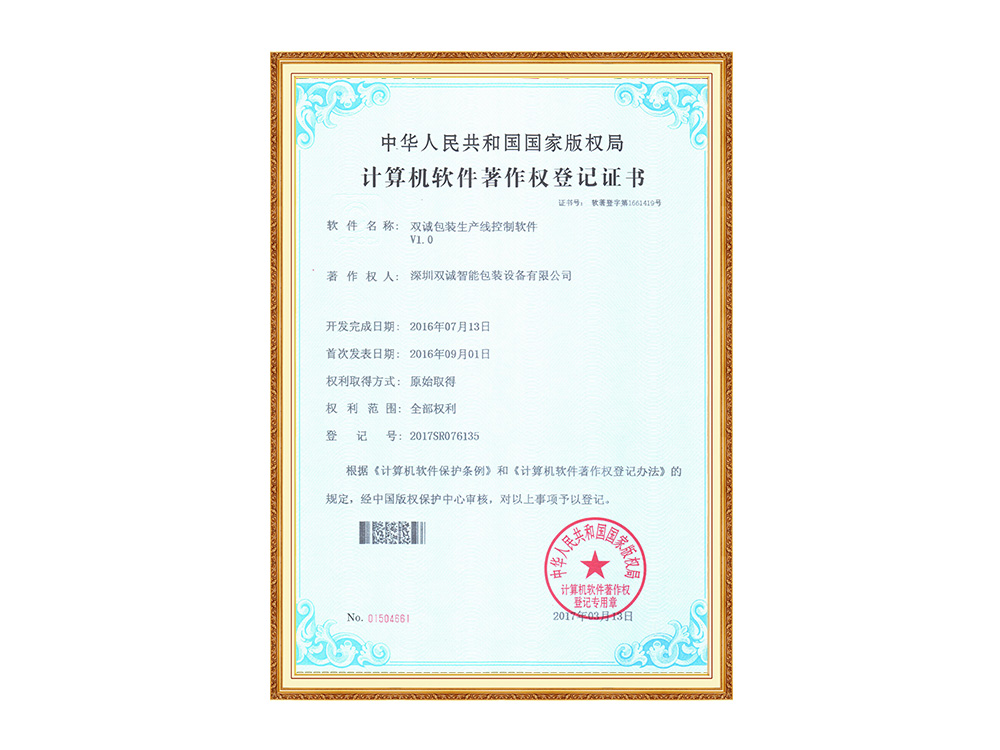

- Servo-Driven Machines: Models like the Servo vertical up and down L-type heat shrink packaging machine offer unparalleled control over film feeding and cutting, reducing waste. Shuangcheng's proprietary control software, evidenced by their SCRC and UMPC technology patents, ensures smooth, programmable operation.

- Integration Potential: Can the machine connect with your existing bagging machine, carton sealer, or strapping machine? Shuangcheng specializes in creating complete back-end packaging assembly lines.

- Ease of Use & Changeover: Look for touch-screen interfaces and quick-adjust mechanisms to minimize downtime when switching products.

Shuangcheng's intelligent control software allows for precise management of packaging parameters, a core advantage of their servo systems.

Step 4: Consider the Manufacturer's Credentials and Support

Your machine is a long-term investment. Partnering with a reliable manufacturer is crucial.

- Experience & Reputation: Established in 2005, Shuangcheng Packaging is a national high-tech enterprise with a 5000 sqm R&D and production facility. Their client list, including SF Express, speaks volumes.

- Technical Support & Customization: Can they provide non-standard side seal shrink wrap equipment for unique applications? Shuangcheng's strong R&D team is equipped for custom solutions.

- After-Sales Service & Global Reach: With exports to Europe, India, and Southeast Asia, ensure the supplier has a network for parts and service. Contact Shuangcheng at scpack@163.com or +86-13823631165 for global support inquiries.

- Certifications & Quality: A strict quality management system and core patents (like their automatic control systems) are indicators of reliable, innovative equipment.

Making the Final Decision: A Checklist

Before you commit, run through this final checklist:

- Have I matched the machine type (L-type, side seal, etc.) to my product's shape and required output speed?

- Does the level of automation (manual, semi-auto, fully auto) align with my labor budget and volume?

- Have I verified the machine's compatibility with my chosen film type and thickness?

- Has the manufacturer (Shuangcheng Packaging or others) provided clear data on energy consumption, footprint, and maintenance needs?

- Is the warranty comprehensive, and is technical support readily available (locally or from the factory in Shenzhen)?

- Have I requested a live demo or case studies, perhaps for a machine like the Servo side seal Shrink Wrap Machine SCT-5545TBC?

For more detailed specifications and to explore their full range of shrink wrap machines, vacuum packaging machines, and complete lines, visit www.shuangchengpack.com.

Choosing the right shrink wrap machine is a strategic decision that impacts your operational efficiency, product protection, and brand image. By methodically assessing your needs against the capabilities of different machines—from standard models to advanced servo L-type sealing, cutting and shrink wrap machines—you can invest in a solution that grows with your business. Partnering with an innovative and experienced manufacturer like Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd. ensures you get not just a machine, but a reliable, high-performance component of your production success.