Navigating the World of Packaging Automation: A Strategic Guide

The global e-commerce boom, accelerated by recent shifts in consumer behavior, has placed unprecedented pressure on logistics and fulfillment centers. Efficient, reliable, and cost-effective packaging is no longer a back-office function but a critical competitive edge. For businesses looking to scale, reduce labor costs, and ensure product safety, investing in the right packaging machine is a pivotal decision. This guide will walk you through the key considerations, from understanding different machine types to integrating them into a seamless packaging line.

A complete packaging line solution integrates multiple machines for maximum efficiency.

Step 1: Assess Your Core Packaging Needs

Before looking at specific models, define your requirements. Are you primarily an E-commerce-packaging-machine user needing to handle diverse product sizes daily? Or are you in food processing, where a fully automatic vacuum packaging machine is essential for shelf life? For logistics giants like SF Express, a partner of Shuangcheng Packaging, high-speed carton sealers and automatic strapping machines are indispensable.

- Product Type & Size: Fragile electronics, irregular shapes, or standard boxes?

- Volume & Speed: How many packages per hour/day do you need to process?

- Primary Function: Sealing, wrapping, bundling, or palletizing?

Step 2: Understand Key Packaging Machine Types

Here’s a breakdown of essential machines and their roles:

1. Carton Forming & Sealing

Carton erectors (like Shuangcheng's SCK-40 series) automatically form flat corrugated sheets into boxes, saving immense manual labor. They are often paired with carton sealers (e.g., SCF-50 models) that apply tape to the top and/or bottom flaps. For e-commerce, an "I-shaped" sealer that tapes the center seam is common and efficient.

2. Shrink Wrapping & Bagging

A shrink wrap machine uses heat to tightly seal products in plastic film, offering protection from dust and moisture. L-type sealers are versatile for various box sizes. A bagging machine is perfect for apparel, soft goods, or placing items into pre-made bags. Shuangcheng's solutions here are crucial for creating retail-ready packages.

3. Strapping & Palletizing

For securing multiple boxes or stabilizing loads, an automatic strapping machine (like the SCD-301) is key. It applies plastic or steel straps quickly and consistently. Finally, a palletizer (robotic or column type) stacks sealed cartons onto pallets for shipping, completing the automation cycle.

Step 3: Evaluate Integration and Smart Features

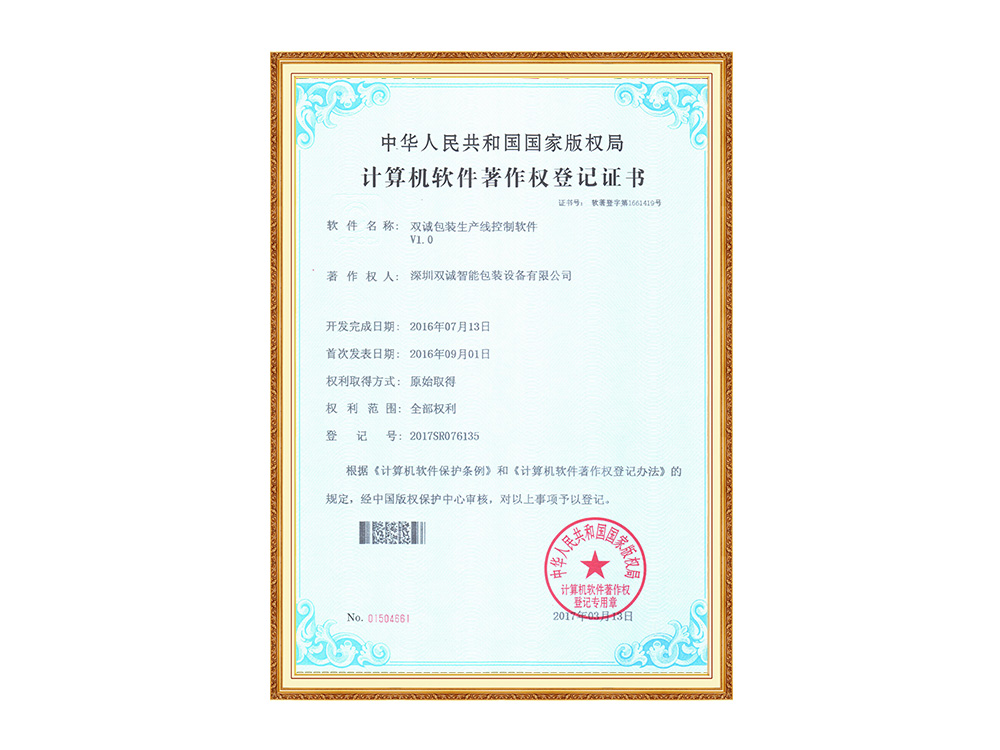

Modern packaging isn't just about mechanical action. Look for machines with intelligent control systems. Shuangcheng Intelligent Packaging, a national high-tech enterprise, develops proprietary software for its equipment. Their systems, visible in their Shuangcheng Packaging Production Line Control Software, allow for pre-programmed settings, speed control, and seamless integration between a carton erector, sealer, and strapper into one smooth packaging line.

Consider features like servo motors for precision, user-friendly touchscreens, and the ability to handle a wide range of materials without frequent adjustment—a must for express packaging machine operations.

Step 4: Consider Supplier Credentials and Support

The machine is only as good as the company behind it. Since its establishment in 2005, Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd. has built a reputation on "honesty is the foundation of business." With a 5000 sqm R&D facility and clients like BYD, they offer more than just hardware.

- Technical Expertise: Can they provide a custom packaging line solution?

- After-Sales Service: Availability of spare parts, remote diagnostics, and on-site support.

- Certifications & Patents: Look for evidence of innovation and quality control.

Step 5: Plan for the Future

Your packaging needs will evolve. Choose a partner and equipment that can scale. Modular machines that can be upgraded or linked to additional units offer long-term value. Whether you're adding a fully automatic vacuum packaging machine for a new food line or a high-speed bagging machine for 3C electronics, flexibility is paramount.

Making the Smart Investment

Selecting the right packaging machine requires a balance of current needs, future growth, and partnership quality. By focusing on your specific application—be it E-commerce-packaging-machine demands or industrial strapping—and partnering with an experienced manufacturer like Shuangcheng Packaging, you invest in more than a machine. You invest in reliability, efficiency, and a foundation for growth.

For a detailed consultation on automating your packaging process, visit www.shuangchengpack.com or contact their team at +86-13823631165 / scpack@163.com.